Eco-Friendly Supply Chain Enhancement

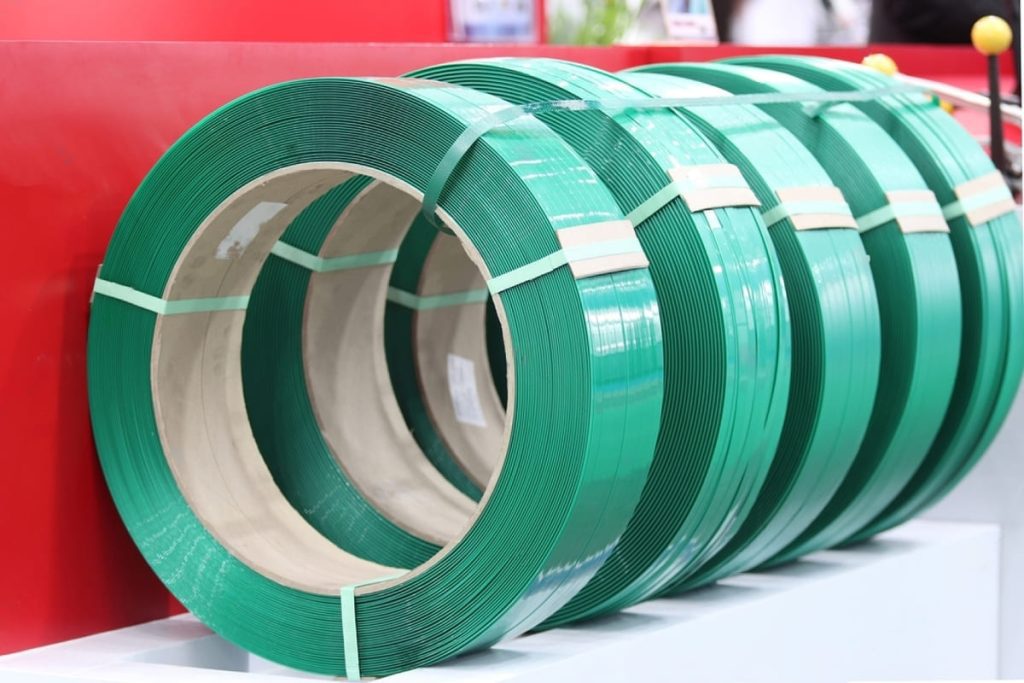

Polypropylene strapping is a versatile polymer product that secures and reinforces boxes and other items during transportation or storage. Many companies have launched successful initiatives to recycle plastic.

Polypropylene strapping: An indispensable component

Polypropylene straps (PP) are plastic straps that reinforce, protect, and group objects or products. All this is during its transportation or storage process.

Characteristics of polypropylene strapping

Its key features include the following:

- Great resistance and flexibility

- It presents a “molded” finish

- Available in various widths

- Corrosion resistant and does not deteriorate

- Perfect for light but not brittle goods

- It is sealed by welding or staples

This kind of strapping can be very affordable for various merchandise.

Applications in the industry

It has numerous uses. They are usually applied to group and fix pallets and boxes, among other merchandise. The strapping provides excellent stability and security during merchandise transfer or storage.

The specialized strapping machine may be manual or automatic, which proceeds to launch the strap. Then proceed to tighten it and seal it with welding or staples. Everything depends on the model.

Generally, they are used to packing or transport items made of different materials. These could be made of cardboard, wood, glass, or food.

Advantages

Compared to other strapping materials, polypropylene strapping offers significant advantages, as we will see below:

- Security and excellent stability to the load.

- Prevention of material damage while being handled.

- They are easy to handle, transport, and store.

- They have excellent resistance to breakage.

Using polypropylene strapping, you will optimize the packaging process while improving the quality of your services.

Environmental impact of plastic strapping and the need for recycling

Polypropylene strapping is one of the easiest to be recycled. This material presents favorable conditions to reduce environmental impact, provided that appropriate techniques are used. Therefore, it is necessary to raise awareness of where plastic comes from and understand the need and importance of recycling.

Negative impact on ecosystems and biodiversity

Plastic harms the ecosystem and biodiversity. Although polypropylene is one of the most used materials for packaging, it is also one of the most significant pollutants. Its decomposition process can last hundreds of years under ordinary conditions, something truly harmful for everyone.

We are talking about a big problem since it causes the alteration and rupture of the environmental balance directly or indirectly. In this sense, it is worth mentioning the impacts commonly caused:

- Pollution in the air

- Generation of toxic waste.

- Water pollution.

- Loss of flora and fauna.

Recycling polypropylene strapping is necessary to avoid such contamination. In addition, costs are minimized by reusing them. On the other hand, the figures and statistics on the production and waste of pp strapping are truly invaluable.

Reduction of environmental impact through recycling and reuse of polypropylene strapping

Recycling polypropylene strapping significantly reduces environmental impact. These are primarily recycled in the food and industrial area. Due to their sustainable materials, they create less waste, so their demand increases daily. Here we present its main benefits:

- Reduction of consumption of raw resources (oil and gas).

- Decrease in the use of electrical energy to produce plastic.

- Less amount of polluting waste.

- Economic.

Correctly recycled strapping can get a longer life in the form of biodegradable strapping. It is the best alternative to contribute to the planet for greater sustainability.

Recycling processes and technologies used

Polypropylene resin code is generally printed with a 5 pp symbol on 5 pp plastics. This model is beneficial for recycling since it shows the type of plastic. So it allows the separation and reuse of material in different compositions.

1. The polypropylene material is separated from other polymer elements. It is done utilizing the technique (sinking-floating).

2. Next, the polypropylene rework contains the melt at a temperature greater than 400 F in an extruder. Then the granulation proceeds so that it can be used in another production.

3. Due to thermal degradation, pp is affected and compromises the structural strength of the plastic. It is because they affect the bonds between the carbon atoms in the polymer chain.

4. Finally, recycled pp is usually mixed with plastic number 5 virgin, up to 50%, to generate new products.

In this way, it is possible to obtain recycled polypropylene. It is worth mentioning that some companies have successfully recycled plastic. We are talking about companies such as SIPA, Ferrero, and Tupperware, among many more.

Promotion of sustainable practices in the handling of polypropylene strapping

It is necessary to raise awareness about the proper handling of polypropylene strapping. In this, it is essential to obtain the collaboration of companies and important actors that promote such an initiative on a large scale. Some of the strategies to promote sustainable practices include:

- Generate strapping recycling cycles.

- Develop action plans to implement new recycling processes.

- Produce more ecological strapping.

In addition, education and training about recycling are of the utmost importance. It favors development and significantly reduces environmental impact. In this way, it will be possible to preserve natural resources while said strapping is used for reuse.

Recycle polypropylene strapping

As you can well appreciate, it is essential to adopt new sustainable measures in the handling of polypropylene strapping. And in addition to making your contribution to the environment, they will also allow you to save. In short, it is an excellent option to contribute to the planet.

So, if you are looking for polypropylene strapping, please do not hesitate to contact us. We are a BMS company specializing in the matter. Do not wait any longer, and we will gladly assist you!